|

April 2014

Clark's Story

By

Paul Harvey

This is the story of a little engine named

Clark - his history and his rebirth. At least we are

told that his name is Clark as no one has ever

seen one like him nor has any records of his birth.

Clark was donated to the museum many years ago by the late

Ralph (Sonny) Wilson of Allegany, New York.

Sonny told us the engine was built by Clark Brothers Company of nearby

Belmont, New York, about

1900. Originally purchased by neighbor Vernon Fields, the engine was

used to power a buzz saw to cut firewood for a maple syrup sugar

shack. Later abandoned in a ditch, Sonny found the engine laying west

of Five Mile Road

near Allegany. Clark had a magneto and gasoline

mixer attached, apparently not original, and, using these, Sonny got him

operational for local displays.

In 1976, for the Olean,

New York Bicentennial, Dresser-Rand, Clark

Brothers successor, adopted him. He received a quick paint job of blue

and silver, the new firm's colors, and had attached a modern

Clark name plate. After the event, they returned

Clark to his owner and, several years later, Sonny donated

the engine to Coolspring

Power Museum.

Clark sat proudly on display in the museum's Expo Building for several

years but, with so many other projects, the museum tucked him away in

safe storage, and he lived, forgotten and in seclusion, for many years.

Then, in November 2013, Mr. Wilson's son, Keith, inquired about

Clark and his life at the museum.

Spurred on by the inquiry, we looked at Clark

and, finding him amazingly interesting, we got him out of storage and

into our heated shop to do a winter rebirth. We were pleased to find

that Clark had very pleasant lines and a most

unusual mechanism. The castings were well done but other parts were

very crudely made. There was no name anywhere on the engine, other than

the 1976 name plate, nor any casting numbers. Being unlike anything

else Clark Brothers ever built made us wonder if

Clark could have been a prototype and the only one in

existence? We will probably never know.

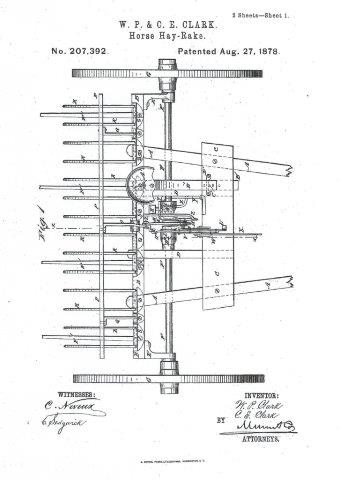

Going back in history over 100 years, we find two brothers

from Belmont, New York,

William Pendleton Clark and Charles Ethan Clark, becoming interested in

the manufacturing business. At that time, the

Belmont area had large farms and huge stands of

timber so they concentrated on products needed to manage these

resources. In 1878, the brothers patented a hay rake; see Photo

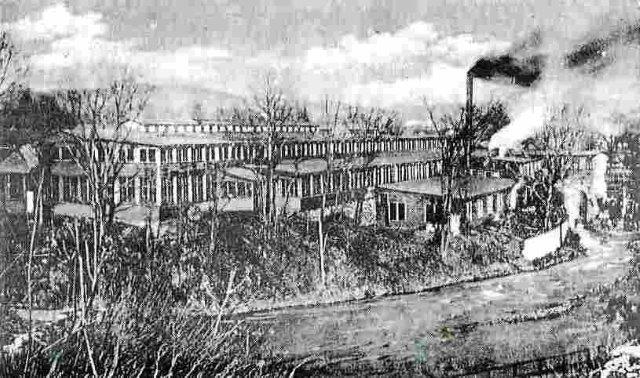

1. Soon they found a great demand for steam engines and sawmill equipment and rapidly rose to be one of the major makers of these

items in the entire country. Photo 2 depicts their plant

in 1908, the largest in Allegany County,

New York. They built huge band saws and Corliss

style steam engines in the 2,000 hp range.

Soon the vast stands of timber were exhausted and the

sawmill trade declined. But a new industry was now in its infancy and

rapidly increasing; oil and gas production and transportation. So a

new chapter opened for the Clark Brothers. William Clark, always the

promoter, looked into the future of the firm while his brother Charles,

now living in Wellsville, New

York, teamed with William Henry Norton in 1907

to found the firm of Clark and Norton. Charles did not leave the Clark

Brothers Company, but remained as vice president while building a

competing firm in Wellsville.

Mr. Norton was educated at Alfred

University, Alfred,

New York, located in

Allegany County,

and already was engaged in the Norton Oil Company and the McEwin-Norton

Oil Company of Wellsville,

New York. He invented the Norton pumping power

and was an accomplished surveyor. In addition to Clark Brothers, the

new firm of Clark and Norton also prospered and built huge oil and gas

pumping equipment. Only about 20 miles apart, they built a parallel

line of equipment and their plant still stands on West Dyke and South

Main Streets in Wellsville. The demand must have been great to support

both firms in harmony with each other!

The destiny of Clark Brothers Company was changed on the

night of May 11, 1912

when a huge fire consumed the plant, a nearby wagon works, and several

houses. A special train brought a Genesee steam

pumper from Wellsville which saved the entire

village of Belmont

from being consumed by the conflagration. Company president William

Clark was in New York City

on business at the time, but brother Charles, vice president, issued a

statement that Clark Brothers would be continued. He volunteered his

other interest, Clark and Norton, to supply orders until the new plant

could be erected. With the new oil and gas industry centered around

Olean, New York, Clark

Brothers decided to rebuild there. So Belmont

again became a quiet agricultural village and the huge new factory was

erected in Olean. This

plant still builds compressors for the Dresser-Rand Corporation. At

this time, the brothers proceeded on their separate ventures - William

in Olean and Charles in

Wellsville.

Moving ahead 100 years, we now return to Clark's

story. Photo 3 shows Clark as

we found him on November 11,

2013, safely tucked away in a storage trailer at the

museum. It had been years since he saw the light of day! Five days

later, and with the nice weather still holding, Clark

was sitting in the shop awaiting the time he would come to life again.

He would have a warm winter home and life was looking good. See

Photo 4. We began to assess the project and found the engine

to be in remarkably good condition. With a little oil and effort, all

parts moved! It was decided that we would decipher the complicated

intake chest and governor, then proceed with a mechanical restoration

keeping the "as received ambience" that told so much of his history.

Complete disassembly and repair would now be required.

The piston, 5½ inches in diameter, slid out easily

revealing three large rings as shown in Photo 5.

Looking closely at the photo, note the odd brass plugs inserted into

the piston at random intervals and machined smooth to the piston

surface. They do not seem to fill any casting defects and have no

apparent use. Another of Clark's mysteries!

Photo 6 shows the intake chest with the rotary throttle. The

small disc to the right containing slots is slightly rotated by the

governor to either align or close the holes in the chest to regulate the

passage of air and gas. This required some lapping with Clover compound

to secure a good seal again. The small plate holds all together.

Clark has a ported cylinder with a

huge 2½ inch diameter exhaust pipe that was well shown in photo

three. Quite unusual for an engine with a 5½ inch piston bore

and a 6 inch stroke. The gases from the exhaust valve are ported

through the head then on through the cylinder to the big exhaust pipe.

As shown in Photo 7, the exhaust is the smaller black

passage to the right in the head. The five other larger openings are

for the cooling water. The exhaust valve has a flat seat and is quite

small and fragile. It is operated by timing gears, push rod, and

rocker arm, all lightly and crudely constructed.

Most interesting is Clark's unusual

governor illustrated in Photo 8. Within one flywheel

are two expanding weights, similar to other engines, that detect the

speed of the engine and spread apart as the speed increases. The

linkage used in the flyweight arms is unfinished flat steel. But there

all similarity to other engines ceases. The arms are connected to two

cast iron shoes that apply pressure to a large cast iron collar. These

parts are very nicely done. As the engine speed increases, the governor

causes the shoes to press tighter on the rim of the collar, rotating it

a bit. The collar has a lever attached and, by means of a linkage,

moves the rotary throttle plate to admit less gas and air. As the speed

decreases, a spring returns the collar, and hence the rotary throttle,

to admit more gas and air. A very unusual and ingenious system!

The bearings were all disassembled, cleaned and measured for

appropriate fit. The rod brass is very nicely made but showed a bit of

wear. Photo 9 shows one half of the bearing mounted in

the shaper to remove 0.004 of an inch of brass. A perfect fit was

obtained with this done to each half. The piston pin and its brass

bushing were also worn as noted in Photo 10. A friend

made the new parts which worked well.

Parts were finished and assembly was proceeding very well.

Photo 11 shows the intake valve chest with the rotary

throttle. A bit complicated but it appears to work well. Similar to

the exhaust, the intake valve has a flat seat and is small and fragile

with a very light return spring. Photo 12 shows the

engine nearly completed. It has been returned to hot tube ignition and

gas (instead of gasoline) as Mr. Wilson suggested. Mounted on a wood

base, it would soon be ready for that first try.

On Saturday, March 1,

2014, Clark was as anxious to run as

we were to "give a try." Oilers were filled and the hot tube burner

lit. Soon the tube was glowing bright orange and it was time to turn on

some gas and spin the wheels. Stewart and Doug begin to crank as seen

in Photo 13. Enthusiasm ran high as the engine

quickly barked into life after so many years of sleeping!

Photo 14 shows a smiling Doug as he adjusts the gas throttle of

the happily running engine. That evening, I forwarded the photo to

Keith Wilson and he replied, "So great, I am sure if my Dad could see

from Heaven, he would be smiling." What a wonderful conclusion to a

very long story!

The Clark engine will now be on

display at Coolspring

Power Museum

for all to see and appreciate. The little engine named

Clark will be happy to greet his visitors. If you are

unable to attend, please go to YouTube and enter "Early

Clark Engine" to spend two minutes watching this event.

You will enjoy! The 2014 Museum schedule can be found on our website,

coolspringpowermuseum.org, or by calling 814-849-6883. See you

then!

|